Leading international Swiss – French – German group with global recognition for its expertise related to environment and particularly in size reduction technologies.

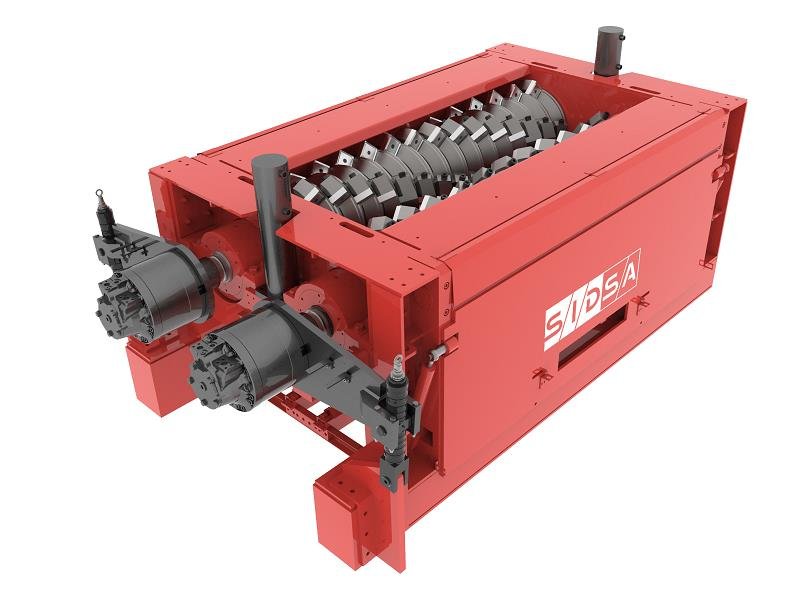

SIDSA

SID - Société Industrielle de la Doux

Leader in the technology for machinery and installations for waste shredding and turnkey projects for waste management.

Leading company worldwide for automated SMP feeding system for Hazardous Waste.

It’s with great reputation in the production of RDF from industrial waste as well as hazardous wastes as solid substitute combustible for incinerators, W2E plants.

The specialist of piston pumps (Solid Pumps), for the pumping of complex material with higher content of dry materials.

SID – Application Areas

MSW treatment plants

WTE – Waste to Energy plants

Sorting and Recycling plants

Cement Industry – waste feeding system for kiln

RDF- Refuse Derive Fuel plants

Incineration plants (Industrial & Hazardous waste)

Composting plants

Production industry (scrap metals) and many more…

Why Shredding is most important?

Waste treatment and disposal

Waste treatment

Incineration

Gasification

Solidification

Heat treatment

Chemical treatment

Waste disposal

Landfills

Underground injection wells

Waste piles

Land treatment

In under developed countries flowing rivers

Todays need is “WASTE TREATMENT”

Efficiency of all waste treatments DependsQuality and Granulometry of waste to be fed

Incineration plants (SMP feeding of rotary kilns)

Cement producers (Shredder & SMP applications)

Sludge conveying for:

Cement producers (sewage)

Water treatment plants

Petrochemical processes

Food industry

Etc.

single piston pumps SPPs (DN 100 – 500, 1 – 40 m3 /h)

double piston pumps DTPP (DN 80 – 400, 1 – 100 m3 /h)

hydraulic drive, software, overall control / integration.

Features of SID Disc Screen:

- Modular design: Integrated Modules of 3m or 4m, Higher separation efficiency and capacity.

- Adjustable screening size: by adjusting distance between shafts (patented)

- Excellent overload protection system:

- Rotation feedback sensor

- Mechanical overload clutch

- PLC program protection loop

- Thermal protection of motor

- Unclogging system: An alarm is triggered when material is clogged

- Quick exchange of shaft assembly: Square shafts design

- Greater speed range: Patented drive clutch design

- Sizing range: 0-40mm, 40-80mm, 80-120mm, 120-200mm

- Maximum capacity (depending on material): 900m³/h

- Rotation speed: 154r/min (variable by frequency inverter)